Grouts machinery

Reeling silk from skeins onto bobbins

Courtesy of Grouts

Putting a twist into the silk yarn

Courtesy of Grouts

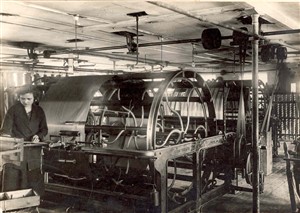

Making silk warps in the 1930s

Courtesy of Grouts

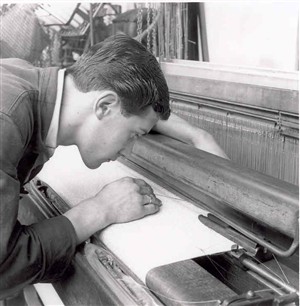

Inspecting the work

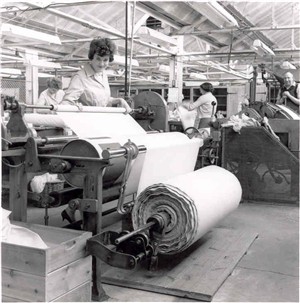

Finished cloth being measured and rolled onto cardboard tubes

Courtesy of Grouts

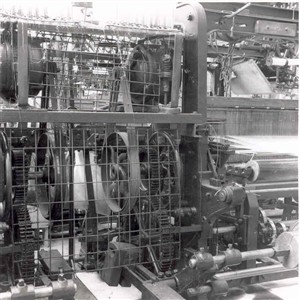

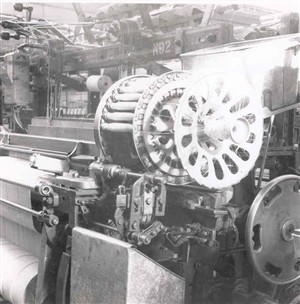

Closeup of the belt-drive guard

Courtesy of Grouts

Bandage Loom

Courtesy of Grouts

Photographs of some of the machinery used by Grouts through the years

By John Layton

Here are some photographs of the machinery and the stages involved in the making of the fabrics produced by Grouts.

The silk arrived in skeins, which had to be wound onto bobbins (photo one)

A twist had then to be put into the thread (photo two)

A 'warp' (lengthwise thread) had to be made, (photo three) which was then ready to load onto the loom. This photograph shows the making of silk warps in the 1930s. The striped warp on the mill in the background is of spun silk.

The crosswise thread ('weft') was then applied using the loom. The finished fabric then had to be inspected for defects (photo four).

The finished fabric was then measured and rolled onto cardboard tubes (photo five), ready for delivery to customers.

The machinery could be dangerous and the belt-drive had to have a guard on it (photo six).

Grouts also made bandages, the loom for which can be seen in photo seven.